Product overview

SZG double cone vacuum drier is a new generation of drying equipment developed by our factory in the light of domestic similar products, double cone vacuum adopts belt - chain two elastic connection mode, therefore, the equipment runs smoothly. The specially designed process fully embodies the good concentricity of the two shafts, and the heat medium and vacuum system adopt reliable mechanical seals or rotary joints of American technology. On this basis, we have developed SZG-A, which can be stepless speed regulation and constant temperature control.

As a professional drying equipment manufacturer, our products range from high temperature heat transfer oil to heat medium, medium temperature steam and low temperature hot water.When drying sticky material, our factory will specially design the "copy board" mechanism or set the ball in the tank for you.

Working principle

◎Heat energy (such as hot water, low pressure steam, or heat conducting oil) is passed through the closed interlayer, and the heat is transferred to the drying material through the inner shell.

◎Under the power driving, the tank rotates slowly, and the materials in the tank are mixed continuously so as to achieve the purpose of strengthening the drying.

◎The material is in a vacuum state, the steam pressure drops, so that the water (solvent) of the material surface reaches saturation state and evaporates, and is discharged and recycled in a timely manner by the vacuum pump. The water (solvent) in the material continuously penetrates, evaporates and discharges to the surface. The three processes are carried out continuously, and the material reaches the drying purpose in a short time.

Adaptive material

Suitable for chemical, pharmaceutical, food and other industries of powder, granular and fiber concentration, mixing, drying and low-temperature drying of materials (such as biochemical products). More suitable for easy oxidation, volatile, sensitive, strong irritant and toxic materials and does not allow the destruction of crystal material drying.

Installation demonstration

Performance characteristics

◎When oil is heated, automatic constant temperature control is adopted. Dry biochemical products can be dried

◎And mineral raw materials, the temperature can be between 20 and 160oC.

◎High thermal efficiency, more than 2 times more than the general oven.

◎Indirect heating. The material is not contaminated and meets the requirements of "GMP". The equipment maintenance is easy to operate and easy to clean.

◎Recommended process placement, demonstration, solvent recovery, process placement.

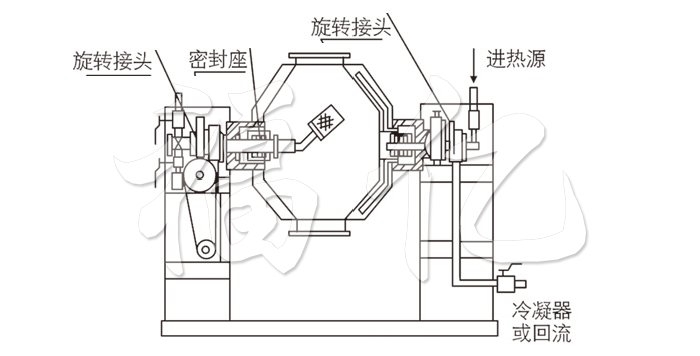

Schematic drawing

Technical specifications

|

Name / specification |

100 |

350 |

500 |

750 |

1000 |

|

Volume |

100 |

350 |

500 |

750 |

1000 |

|

Charging volume (L) |

≤50 |

≤175 |

≤250 |

≤375 |

≤500 |

|

Heating area (m2) |

1.16 |

2 |

2.63 |

3.5 |

4.61 |

|

Speed (rpm) |

4 - 6 |

||||

|

Motor power (kw) |

0.75 |

1.1 |

1.5 |

2 |

3 |

|

Area covered L×W(mm) |

2160×800 |

2260×800 |

2350×800 |

2560×1000 |

2860×1300 |

|

Slewing height (mm) |

1750 |

2100 |

2250 |

2490 |

2800 |

|

Tank design pressure (Mpa) |

-0.1-0.15 |

||||

|

Jacket design pressure (Mpa) |

≤0.3 |

||||

|

working temperature (oC) |

Inner tank≤85 jacket≤140 |

||||

|

When using condensers, vacuum pumps |

2X-15A |

2X-15A |

2X-30A |

2X-30A |

2X-70A |

|

Power |

2KW |

2KW |

3KW |

3KW |

505KW |

|

When no using condensers, vacuum pumps |

SK-0.4 |

SK-0.8 |

SK-0.8 |

SK-2.7B |

SK-2.7B |

|

Power |

1.5KW |

2.2KW |

2.2KW |

4KW |

4KW |

|

Weight (kg) |

800 |

1100 |

1200 |

1500 |

2800 |

|

Name / specification |

1500 |

2000 |

3500 |

4500 |

5000 |

|

Volume |

1500 |

2000 |

3500 |

4500 |

5000 |

|

Charging volume (L) |

≤750 |

≤1000 |

≤1750 |

≤2250 |

≤2500 |

|

Heating area (m2) |

5.58 |

7.5 |

11.2 |

13.1 |

14.1 |

|

Speed (rpm) |

4 - 6 |

||||

|

Motor power (kw) |

3 |

4 |

5.5 |

7.5 |

11 |

|

Area covered L×W(mm) |

3060×1300 |

3260×1400 |

3760×1800 |

3960×2000 |

4400×2500 |

|

Slewing height (mm) |

2940 |

2990 |

3490 |

4100 |

4200 |

|

Tank design pressure (Mpa) |

-0.1-0.15 |

||||

|

Jacket design pressure (Mpa) |

≤0.3 |

||||

|

working temperature (oC) |

-0.1-0.15 |

||||

|

When using condensers, vacuum pumps |

JZJX300-8 |

JZJX300-4 |

JZJX600-8 |

JZJX600-4 |

JZJX300-4 |

|

Power |

7KW |

9.5KW |

11KW |

20.5KW |

22KW |

|

When no using condensers, vacuum pumps |

SK-3 |

SK-6 |

SK-6 |

SK-9 |

SK-10 |

|

Power |

5.5KW |

11KW |

11KW |

15KW |

18.5KW |

|

Weight (kg) |

3300 |

3600 |

6400 |

7500 |

8600 |

Note: for the material that varies greatly before and after drying, the loading coefficient can be enlarged or reduced.